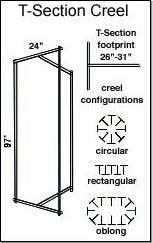

T-Section Creels

T-Section Creels

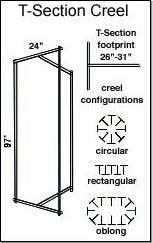

- Flexible positioning feature allows oval, circular and rectangular configurations.

- Number of machine feeds can be increased or reduced by simply adding or removing “T” sections.

- Pre-assembled sections allow for easy installation.

Specifications

The Creel Systems, along with our vacuums, isolation rooms, and Rotolator 360®, were product innovations designed, developed and tested to overcome challenges in our knitting mill. At Alandale Industries, we know how important it is to keep your knitting machines producing top quality fabrics, year after year. Let Alandale be your single-source supplier for all your creel system needs

Accessories

| T-Section Design |

|

- Sections are made with durable steel tubing

- Collapsible design allows for ease of shipment.

|

| Yarn Tubing |

|

- Straight, anti-static tubing is available in aluminum or rigid, carbon impregnated PVC (black) styles

- Adjustable telescopic design allows for easy installation

- Ceramic elbows reduce friction

- Flexible tubing is available in standard or crimped styles. Crimped tubing is offered exclusively by Alandale and significantly reduces tension on yarn.

|

| Creel Fans |

|

- Designed to eliminate lint buildup on cones

- Durable, long-lasting motors are maintenance free

|

| Swing Out Cone Pins |

|

- Snap-open, snap-close feature makes loading cones of yarn easier and more efficient

- Swing-out design reduces wrist fatigue

- Accepts any standard cone size

- Standard equipment with all creels

|

| Air Jet Threading System |

|

- Reduces labor costs

- Eliminates the need for air guns and hoses when threading yarn through tubes.

- Quick and easy to use

- Retrofits to existing creels

|

| Creel Numbering System |

|

- Corresponding numbers on creel and machine make threading easier.

- Large vinyl-coated numbers from 1 to 120 are durable and easy to read.

|

| Safe-T-Air-Gun |

|

- Cleans hard-to-reach surfaces easily with its long, rigid nozzle design.

- Conforms to all United States OSHA safety standards. Performance and safety tests based on 90 pounds maximum inlet pressure.

- Unique nozzle design provides an extra boost in cleaning power and is available in short or long styles.

|

T-Section Creels

T-Section Creels